2026 Best Ball Screw for Sale What to Consider

When considering the 2026 best ball screw for sale, it’s important to approach the purchase thoughtfully. Renowned industry expert, Dr. Alice Roberts, once stated, “Choosing the right ball screw can significantly impact your project’s efficiency.” Her insight emphasizes the need to evaluate various factors extensively.

Understanding the specifications is crucial. From load capacity to size, each detail shapes the final decision. Potential buyers should prioritize quality and durability over price. Low-cost options may tempt you, yet they often lack reliability. Every decision carries weight and requires reflection on performance.

Moreover, consider the application of the ball screw. A tailored approach can prevent costly mistakes later. Remember, this is an investment in your machinery’s performance. Neglecting the fine details may lead to unanticipated challenges down the line. Keep in mind the importance of not just finding a ball screw for sale, but selecting the right one to enhance operational success.

2026 Best Ball Screw Overview: Key Features and Performance Metrics

When choosing a ball screw, it's crucial to focus on specific performance metrics. The load capacity and efficiency are vital. A higher load capacity means better performance in demanding applications. You should also consider the lead of the screw. It affects the speed and accuracy of the system. A shorter lead provides greater precision, while a longer lead allows for faster movement.

Thermal expansion can impact performance as well. Materials used in ball screws often have different thermal expansion rates. This can lead to misalignment. It's essential to select screws that can handle temperature variations effectively. Look for features like preloading to enhance rigidity. Preloaded screws can reduce backlash, increasing precision during operation.

Noise levels during operation deserve attention. Some designs minimize noise, which is crucial in sensitive environments. However, not all options are equally quiet. Testing in actual conditions is often necessary. Reflect on what you need most: speed, accuracy, or reduced noise. Your choice will depend on specific applications and settings. Make sure to weigh these factors carefully.

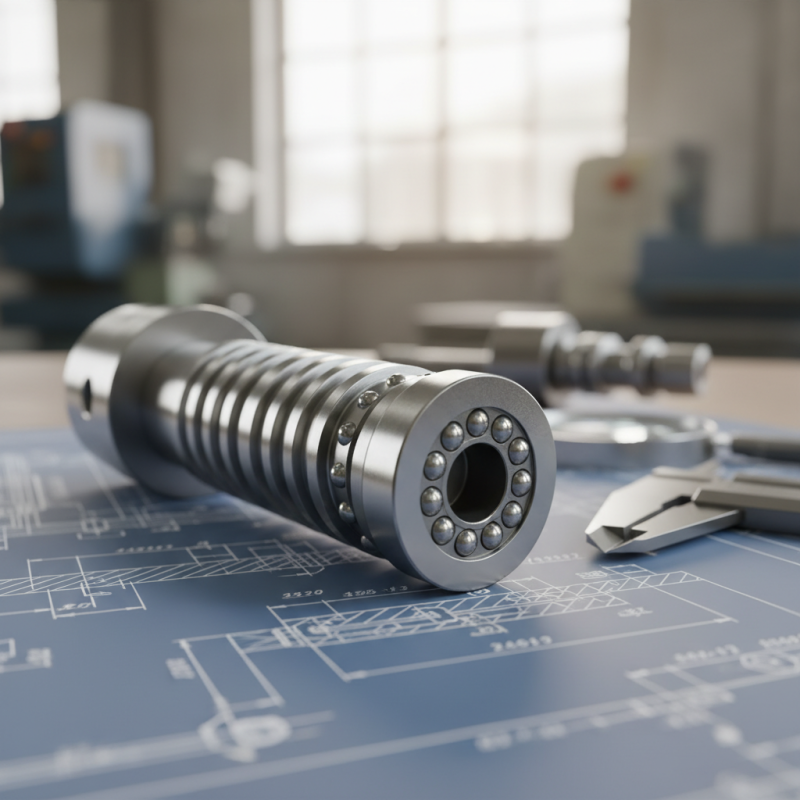

Types of Ball Screws: Choosing Between Standard, Miniature, and Precision Models

When selecting a ball screw, the type significantly impacts performance. Standard models are widely used. They offer reliability for many applications. Typically, they come in various sizes and lead options. However, they might not meet precision needs in crucial tasks.

Miniature ball screws are ideal for space-constrained situations. Their compact design allows for efficient integration into small machines. These screws are lightweight, but they may have lower load capacities. Users often find themselves balancing size with strength. Precision ball screws deliver high accuracy and repeatability. They are essential for applications requiring tight tolerances. However, the cost can be higher than standard alternatives. Users must evaluate their budget against precision needs.

Ultimately, each type of ball screw serves a purpose. Ignoring application specifics can lead to poor decisions. It is wise to reflect on the operational demands before making a choice. Some users may prioritize price over quality. This can result in decreased efficiency and increased maintenance. A thoughtful approach to selecting the right ball screw makes a real difference.

Material Composition: The Impact of Steel, Aluminum, and Coatings on Longevity

When selecting a best ball screw, material composition is crucial. The most common materials are steel and aluminum. Each has its own benefits and drawbacks. Steel offers high strength and durability. It can withstand heavy loads and harsh conditions. However, it may be prone to rust if not properly coated. Aluminum, on the other hand, is lightweight. It resists corrosion well, but lacks the same load-bearing capacity as steel.

Coatings also play a significant role. They protect against wear and enhance lifespan. A good coating can reduce friction too. This leads to smoother operation. But not all coatings are equally effective. Some wear off quickly. It’s essential to choose a quality finish.

**Tips**: Always check the specifications of the materials. Ensure the right choice for your applications. If unsure, consult with professionals. They can provide insights specific to your needs. Don’t overlook the importance of material properties. What seems minor can greatly impact performance over time. Always aim for a balance in performance and longevity.

Load Capacity and Efficiency: Understanding Critical Specifications for Selection

When selecting a ball screw, load capacity and efficiency are key specifications. The load capacity tells you how much weight the screw can handle. It is crucial to match this to your application. A higher load capacity usually means better strength. However, this can also increase costs. Efficiency plays another important role. It impacts how much energy is consumed. A more efficient ball screw reduces waste. This saves money in the long run.

Tips: Consider your machine's requirements. Heavy-duty applications need robust screws. Lighter tasks might not require high capacity. Analyze your workload carefully. Efficiency ratings can vary widely. Sometimes, a more costly model is actually cheaper over time.

Choosing the right ball screw is not always straightforward. While you may need it for specific functions, other factors can complicate your choice. Overlooking dimensions could lead to issues. Ensure you measure correctly. Also, consider the environment. High temperatures or moisture can affect performance. Always remember, not all ball screws fit all designs. Take time to evaluate your needs.

2026 Best Ball Screw for Sale: What to Consider - Load Capacity and Efficiency

| Model | Load Capacity (kg) | Efficiency (%) | Diameter (mm) | Length (mm) | Lead (mm) |

| BS1001 | 500 | 90 | 20 | 1000 | 5 |

| BS1002 | 750 | 85 | 25 | 1500 | 10 |

| BS1003 | 1000 | 88 | 30 | 1200 | 12 |

| BS1004 | 600 | 92 | 20 | 800 | 5 |

| BS1005 | 900 | 87 | 25 | 1100 | 10 |

Cost Considerations: Evaluating Price vs. Performance in Ball Screw Procurement

When selecting a ball screw, cost considerations play a crucial role. A recent industry report indicates that the total lifecycle cost can vary significantly. This cost includes not only the initial purchase price but also maintenance and operational expenses. A cheaper ball screw might seem appealing upfront. However, it can lead to higher maintenance costs over time. This highlights the importance of evaluating price versus performance.

Performance metrics are essential for long-term value. Research shows that high-quality ball screws can increase efficiency by up to 30%. Poor-quality options, while cheaper, may result in frequent failures. Consequently, businesses face increased downtime and repair costs. It’s important to weigh these factors in procurement decisions.

Material quality is another significant aspect to consider. Reports indicate that ball screws made with high-grade stainless steel offer greater durability. They can withstand higher loads and speeds. Ensuring the right specifications can prevent costly replacements. Hence, mere price should not be the only deciding factor. A more expensive choice may prove more economical in the long run. Optimal performance and reliability should guide your selection process.

2026 Best Ball Screw Cost vs. Performance Evaluation