What is a Sludge Press and How Does it Work in 2026?

In 2026, the significance of a Sludge Press is more pronounced than ever. Industry expert Dr. Emily Carter states, "A Sludge Press is essential for sustainable waste management." This equipment plays a crucial role in treating waste from various industries. It helps separate solids from liquids, reducing disposal challenges.

Many facilities now rely on advanced Sludge Press technology. These machines are essential for optimizing waste treatment processes. Their efficiency directly impacts environmental protection. However, not all systems perform at the same level. Some older models struggle with energy consumption and maintenance issues.

Continuous improvement in technology is vital. A well-functioning Sludge Press can save costs and enhance waste management. Still, some users experience operational difficulties. Regular evaluation of Sludge Press systems is necessary to ensure they meet current standards. Balancing efficiency and cost can be complex, highlighting the need for ongoing discussions in the industry.

What is a Sludge Press? Definition and Overview

A sludge press is a mechanical device used in wastewater treatment. Its primary function is to extract water from sludge, concentrating solid waste for easier disposal. By applying pressure, the sludge press separates the liquid from the solids. This process reduces the overall volume, making transportation and disposal more efficient.

The operation of a sludge press involves several stages. In the first stage, sludge enters the device, where it is evenly distributed. As the process continues, pressure is slowly applied to force water out of the sludge. Operators may notice wear and tear on parts over time. Regular maintenance helps keep the unit functional. However, some operators overlook this, resulting in inefficiency and increased costs.

Understanding how a sludge press works is crucial. It is not just about pressing sludge; it's about managing resources wisely. While the technology has advanced, challenges remain. For example, if the sludge isn't properly conditioned, separation can fail. This leads to higher operational costs and environmental concerns. Addressing such issues requires ongoing training and awareness in the field.

The Purpose of Sludge Presses in Wastewater Treatment Systems

Sludge presses are vital in wastewater treatment systems. They separate solids from liquid waste, helping in waste reduction. Over time, this process has evolved, making it more efficient. In 2026, these machines play a crucial role in managing the byproducts of wastewater.

The purpose of sludge presses is to dewater sludge effectively. This process reduces the volume of waste significantly. By applying pressure, water is squeezed out, leaving behind a solid mass. This solid can be disposed of or reused as fertilizer. However, challenges still exist. Some types of sludge may not dewater easily. Understanding the specific characteristics of the sludge is essential for optimal performance.

Tip: Regular maintenance of the sludge press can prevent costly breakdowns. Check for wear and tear on components. Another tip is to monitor the properties of the incoming sludge. This helps in adjusting the process effectively. Not all wastewater is created equal, and adaptability is key. Sometimes, the results may not meet expectations. Reflecting on the operation can lead to improvements.

Key Components and Design Features of Modern Sludge Presses

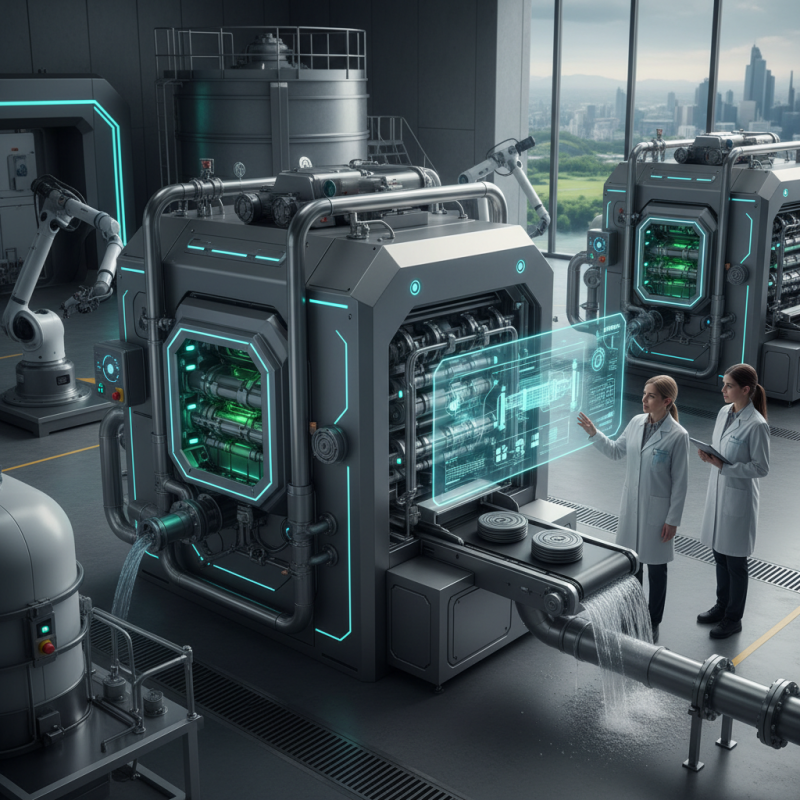

Modern sludge presses have evolved significantly with advanced design features aimed at improving efficiency and sustainability. A key component is the screw mechanism, which effectively compacts and dewaters sludge. This element ensures that materials are efficiently transported through the system. Additionally, the frame is typically constructed from durable steel, providing stability during operation. This strength is essential as the process involves high pressure.

Another vital element is the control system. Many presses now utilize smart technology to monitor parameters. These systems provide real-time feedback on performance. Operators can adjust settings remotely, enhancing flexibility. Some designs incorporate a dewatering component that functions in multiple stages. This step-by-step approach can lead to greater material recovery, yet it also introduces complexity in maintenance.

While these features offer clear benefits, challenges remain. Issues with clogging can occur if the feedstock is not adequately managed. Furthermore, the initial setup cost can be substantial. Many facilities might struggle with justifying the investment. Such considerations highlight the need for thorough evaluations before implementation. Each facility needs to weigh the pros and cons carefully to achieve the best results.

How Sludge Presses Operate: A Step-by-Step Process

A sludge press is a critical device in wastewater treatment. It efficiently reduces the volume of sludge generated during the treatment process. Understanding how it operates is essential for industry professionals.

The sludge press uses mechanical pressure to dewater sludge. Initially, the sludge is pumped into the press. The system employs a series of plates to apply significant pressure to the material. This pressure forces out water from the sludge, leaving behind a solid cake. According to recent data, effective dewatering can reduce sludge volume by up to 90%. This is a game-changer for managing waste in treatment facilities.

Additionally, the process can be observed in stages. After the material enters, it undergoes flocculation—chemicals help bind the solids together. Then the pressing stage occurs. The cake formation happens next. Researchers note that optimizing this process is crucial. Some facilities struggle with inconsistent sludge quality, affecting dewatering efficiency. These challenges highlight the need for continuous improvement in operating techniques.

Benefits and Challenges of Using Sludge Presses in 2026

The use of sludge presses in 2026 reveals multiple benefits and challenges. Sludge presses efficiently reduce waste volume. This not only saves space but also minimizes disposal costs. Dehydrating sludge is crucial for municipalities. It helps them manage waste sustainably. As environmental concerns grow, a sludge press becomes increasingly relevant.

However, there are challenges in using this technology. Initial costs can be significant. Not all facilities can afford the investment. Maintenance is another concern. Presses require regular upkeep. Neglect can lead to inefficiencies and increased operating costs. The process can sometimes produce odors, which is a drawback for nearby communities.

Modern sludge presses also demand technical expertise. Staff need training to operate them effectively. This challenges facilities already stretched thin on resources. While the benefits are clear, careful consideration is necessary. Balancing efficiency with practicality remains a constant reflection point for operators.