Ultimate Tips for Choosing the Right Autoclave Vessel?

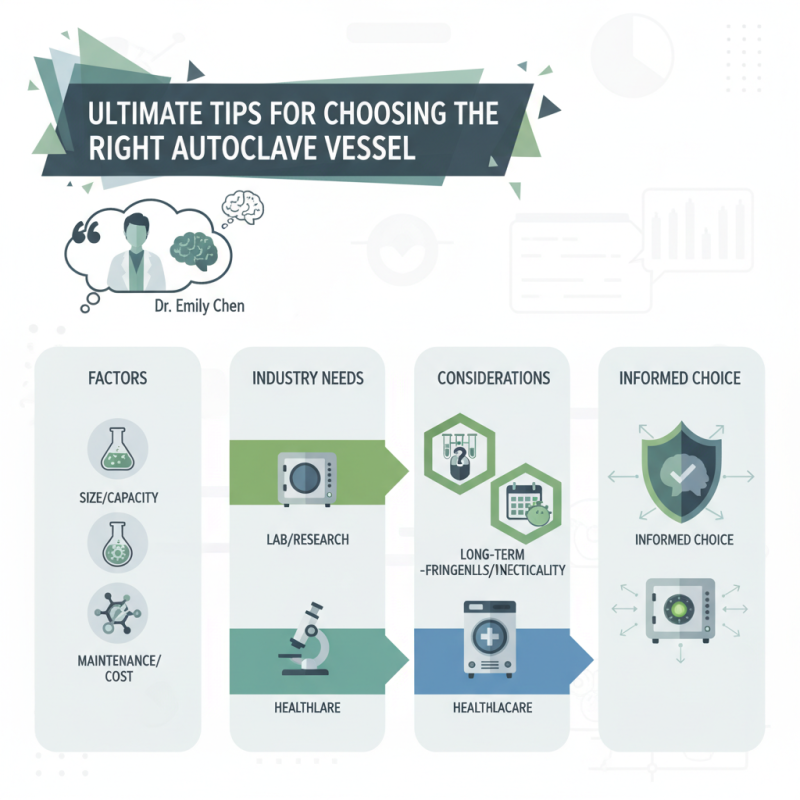

Choosing the right Autoclave Vessel is crucial for various industries, from healthcare to research. Dr. Emily Chen, an expert in sterilization technology, emphasizes, "Selecting the right autoclave vessel can significantly impact your workflow and safety." This statement highlights the importance of making an informed choice.

When considering an autoclave vessel, various factors come into play. Size, capacity, and material must align with your specific needs. For instance, a lab might require a smaller unit for compact space. In contrast, a hospital may need a larger vessel to process more equipment simultaneously.

The decision-making process can be complex. You might find yourself drawn to the latest models or features. However, it’s essential to reflect on practical aspects, like maintenance and cost. Don’t overlook how user-friendly the design is. A complicated interface can hinder efficiency, causing frustration when users seek to sterilize items properly. Recognizing these factors can guide you in making a more reflective decision.

Understanding the Importance of Autoclave Vessels in Sterilization

Autoclave vessels play a crucial role in sterilization processes. They are essential for ensuring that equipment and materials are free from harmful microorganisms. This is vital in medical, laboratory, and industrial settings. Their importance cannot be overstated. Without proper sterilization, health risks increase, and contamination might occur.

When choosing the right autoclave vessel, consider its size and capacity. Evaluate what you need to sterilize. Smaller vessels are suitable for limited items, while larger ones accommodate bulk sterilization. Think about the materials used in construction. Some vessels can withstand high temperatures better than others. This impacts their longevity and reliability.

It’s important to reflect on your specific requirements. Not all vessels work well in every context. Compatibility with the sterilization method is key. Efficiency matters too. Select a model that provides consistent results. Regular maintenance is necessary to ensure optimal performance. Always assess your choice. An ill-fitting vessel can lead to failures in sterilization.

Key Factors to Consider When Selecting an Autoclave Vessel

Choosing the right autoclave vessel is crucial for effective sterilization. You need to consider several key factors during this process. The size of the vessel is vital. Ensure it fits your sterilization needs. Think about the volume of items you will treat regularly. A smaller vessel may lead to multiple cycles, which can be time-consuming.

Material selection is another important aspect. Stainless steel is popular for its durability and resistance to chemicals. However, some processes may require specific materials for optimal performance. Reflect on what materials are compatible with your applications. The design of the vessel also matters. Look for features that promote good steam circulation. This can enhance efficiency and ensure proper sterilization.

Temperature and pressure ratings should not be overlooked. Different applications require different settings. Ensure the vessel can handle the necessary conditions. Regular maintenance and inspection of the vessel are also crucial. This helps maintain performance and safety over time. Balancing these elements can be challenging, but it is essential for effective sterilization.

Material Choices for Autoclave Vessels: Pros and Cons

When selecting an autoclave vessel, the material is crucial. Common choices include stainless steel, glass, and aluminum. Each has unique characteristics that can impact performance.

Stainless steel is known for its durability. It withstands high temperatures and pressure well. It is resistant to corrosion and easy to clean. However, it can be heavy and costly. Some users report scratches over time, affecting longevity.

Glass vessels offer excellent visibility. It's easy to monitor the contents, which is important during sensitive processes. Yet, glass can be fragile, prone to cracks if mishandled. It also may not hold up well over time under extreme conditions. Evaluating these factors is essential for safe and effective use.

Size and Capacity: Finding the Right Fit for Your Needs

Choosing the right autoclave vessel starts with understanding size and capacity. Selecting a vessel too small may require multiple cycles, increasing time and energy costs. The average laboratory vessel ranges from 50 liters to over 300 liters. According to a recent industry report, 70% of users prefer vessels that align with their specific needs.

Capacity directly impacts effectiveness. Each autoclave has a unique capacity range, which affects sterilization efficiency. A report by the Sterilization Association noted that 30% of users reported inefficient sterilization when the vessel was overfilled. It’s essential to evaluate your typical load. Equipment and materials should fit comfortably, allowing proper steam circulation.

Think about future needs too. Facilities may expand or change focus. The initial choice of vessel size could limit options later. However, larger vessels can consume more energy and space. It’s a balancing act. Consider not just your immediate requirements, but also potential growth. The decision should be informed and strategic.

Ultimate Tips for Choosing the Right Autoclave Vessel

| Vessel Size (Liters) | Max Capacity (Kg) | Ideal for | Recommended Applications |

| 5 | 10 | Small Labs | Petri Dishes, Small Instruments |

| 10 | 20 | Medium Labs | Flasks, Beakers, Instruments |

| 20 | 40 | Large Labs | Large Instruments, Batches |

| 30 | 60 | Industrial Use | Medical Waste, Large Volumes |

Maintenance and Safety Features to Look for in Autoclave Vessels

When selecting an autoclave vessel, maintenance and safety features are critical. Regular maintenance ensures efficient operation. Look for models with easy access points for cleaning. A simple design often means fewer places for bacteria to hide. Check how user-friendly the maintenance procedures are. Complicated steps can lead to neglect, which is dangerous.

Safety features are just as important. An effective safety lock can prevent accidental openings during cycles. Overpressure valves and temperature controls are essential too. They help avoid dangerous situations. Look for indicators that alert you to these issues. These notifications can make a big difference in a busy environment.

Consider assessing the vessel's materials. Corrosion-resistant materials are ideal for longevity. Regular inspections are vital, as flaws can develop over time. Look for clear manuals that guide you through maintenance. A lack of detail can lead to mishaps and confusion. Always question if you are getting the right safety features for your needs. Choosing wisely protects both you and your equipment.